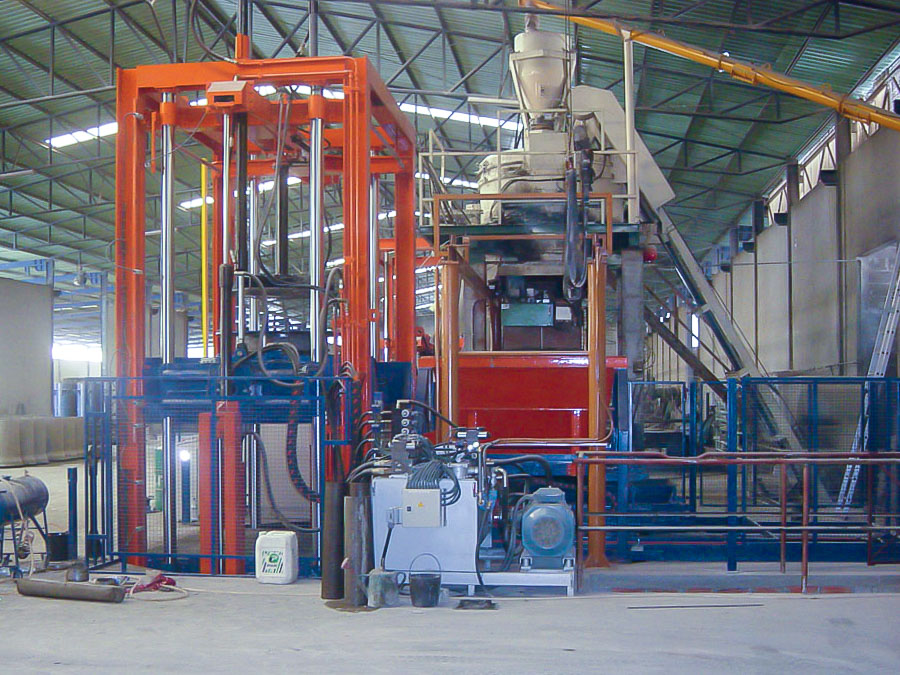

AUTOMATIC SERIES

VOLTAMIX

MACHINE FOR MANUFACTURING CONCRETE PIPE WITH TURNING SYSTEM FOR MANUFACTURING SPECIAL CONCRETE PIECES.

PRODUCTIVITY

multiple production

SUPERIOR QUALITY

surface finish

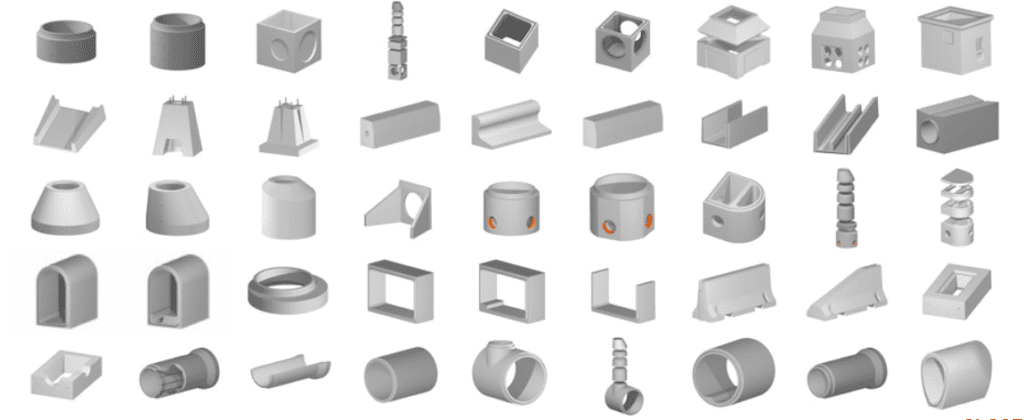

VERSATILITY

wide range of concrete products

K-2500 M0

Hydraulic-electric semi-automatic machines

K-2500 M1

Hydraulic-electric semi-automatic machines

K-2500 M2

Box culverts with modular panels